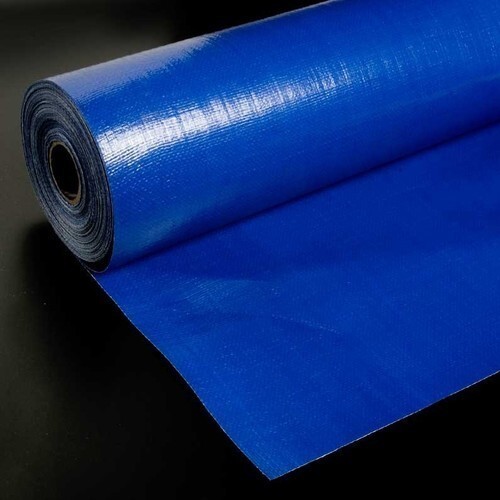

Ldpe Tarpaulin sheet

Price 70.0 INR/ Kilograms

Ldpe Tarpaulin sheet Specification

- Type

- Sheet Tarpaulin

- Material

- Low-Density Polyethylene (LDPE)

- Tensile Strength

- Excellent, as per IS: 2508 standards

- Working Temperature

- -20C to +60C

- Density

- 0.92 Gram per cubic centimeter(g/cm3)

- Length

- 10m to 50m (custom lengths on request)

- Width

- 3m, 4m, 5m, 6m (other widths available on request)

- Thickness

- 150 to 300 microns

- Transparency

- Opaque

- Hardness

- Flexible

- Size

- Custom sizes available

- Color

- Blue, Green, Yellow, Black (subject to availability)

- Weight

- Varies by thickness and size, approx. 140-280 GSM

- Usage

- Agriculture, construction, covering storage goods, temporary shelters

- Cold Crack Resistance

- Good cold crack performance

- Surface Finish

- Matte/smooth finish

- Lamination

- Multi-layer LDPE

- Fire Retardant

- Optional as per requirement

- Reinforcement

- Heat-sealed edges and reinforced corners

- Packaging

- Packed in rolls or folded bundles

- UV Resistance

- UV stabilized for outdoor durability

- Waterproof

- 100% waterproof

- Chemical Resistance

- Resistant to most chemicals and acids

Ldpe Tarpaulin sheet Trade Information

- Minimum Order Quantity

- 100 Kilogram

- Supply Ability

- 4000 Per Month

- Delivery Time

- 3-5 Days

About Ldpe Tarpaulin sheet

Backed by a team of droit professionals, we are involved in providing Ldpe Tarpaulin sheet to our customers. We professionals manufacture this machine by making use of premium quality components and latest technology in accordance with international standards. In order to deliver defect free range at customers end, this Ldpe Tarpaulin sheet is stringently tested by our quality controllers against different parameters. a

Exceptional Durability for Outdoor Conditions

This tarpaulin sheet undergoes UV stabilization, making it suitable for prolonged use in direct sunlight without degrading. Its flexible LDPE construction allows it to withstand temperature variations from -20C to +60C, and it remains resistant to cracking in cold climates. From intense summer heat to winter frost, the sheet provides consistent protection for your assets and goods.

Tailored for Varied Industrial Applications

With a density of 0.92 g/cm and reinforced construction, the tarpaulin finds extensive use across agriculture, construction, storage, and temporary shelters. Multi-layer lamination ensures superior waterproofing and chemical resistance, safeguarding goods from moisture and hazardous substances. Its customizable dimensions make it suitable for both small-scale and large-scale industrial applications.

FAQs of Ldpe Tarpaulin sheet:

Q: What types of environments are suitable for using LDPE UV-resistant tarpaulin sheets?

A: These tarpaulins are engineered to perform excellently in outdoor environments with exposure to sunlight, moisture, and temperature extremes. They are widely used in agriculture, construction, storage facilities, and even as makeshift shelters due to their UV resistance, waterproof properties, and robust build.Q: How does the UV stabilization benefit the tarpaulin sheet during outdoor use?

A: UV stabilization protects the tarpaulin from damage caused by prolonged sunlight exposure, significantly extending its lifespan and maintaining strength and flexibility even under direct sun. This feature is particularly beneficial for applications where the sheet is continuously exposed to outdoor elements.Q: What is the process involved in reinforcing the tarpaulin sheet for enhanced durability?

A: Reinforcement is achieved through heat-sealed edges and additional corner strengthening, preventing tearing and fraying. The multi-layer LDPE lamination provides further resilience, resulting in a sheet that holds up under mechanical stress and variable weather conditions.Q: Where can these LDPE tarpaulin sheets be typically used?

A: They are commonly deployed in agricultural settings for crop and hay protection, at construction sites for covering materials and machinery, as storage covers for industrial goods, and for setting up temporary shelters and tents in outdoor environments.Q: What are the available customization options for size, color, and packaging?

A: Tarpaulin sheets can be produced in custom sizes (lengths 1050 meters, widths from 3 to 6 meters, others upon request). Standard colors include blue, green, yellow, and black, subject to availability. Packaging options comprise rolled or folded bundles for ease of transport and storage.Q: How do the water and chemical resistance features benefit the usage of this tarpaulin?

A: Being 100% waterproof and chemically resistant, the sheet protects stored goods, agricultural produce, and construction materials from water damage and many types of acidic or corrosive chemical exposure, keeping them dry and safe in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LDPE Tarpaulins Sheets Category

Ldpe Sheet For VDF Flooring and Road construction

Price 72.0 INR / Kilograms

Minimum Order Quantity : 100

Hardness : Other

Type : Other

Material : ldpe

Color : Black

Ldpe Polythene Sheet

Price 70.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Hardness : Soft

Type : Other, Ld Polythene Sheet

Material : LDPE

Color : Black

LDPE blue tarpaulin sheet

Price 50 INR / Ton

Minimum Order Quantity : 100 Tons

Hardness : Soft

Type : Other, Tarpaulin Sheet

Material : Hdpe

Color : Blue

LDPE Sheets

Price 50.0 INR / Ton

Minimum Order Quantity : 100 Tons

Hardness : Soft

Type : Other, Ldpe Sheet

Material : LDPE

Color : Blue

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS